United States Patent: #9,512,621

Florida Product Approval: #FL14427

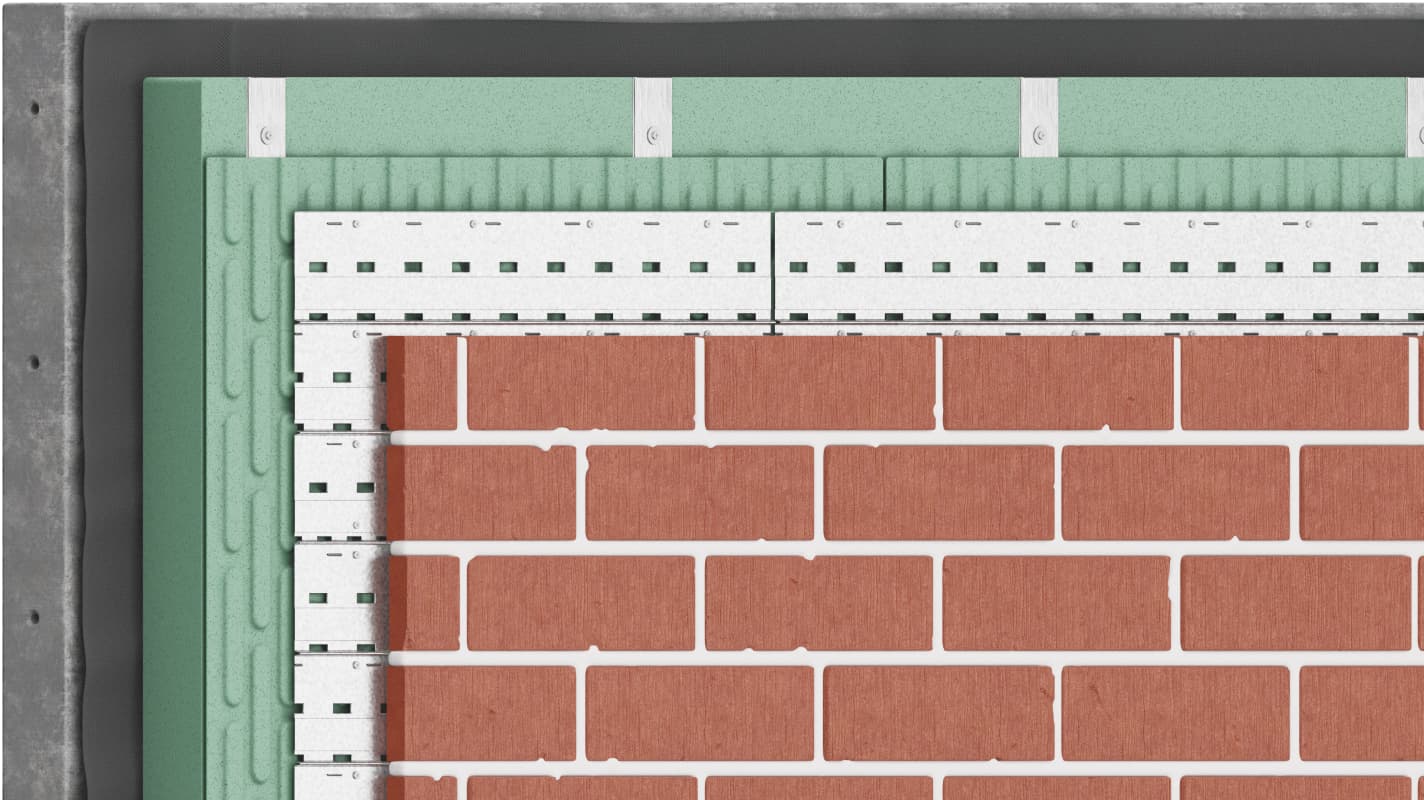

The Brick it™ Moisture Control System (CI) combines the structural and ease-of-installation features of DMG with the capabilities of MCS and adds additional continuous insulation properties to meet the latest building codes often required in commercial applications.

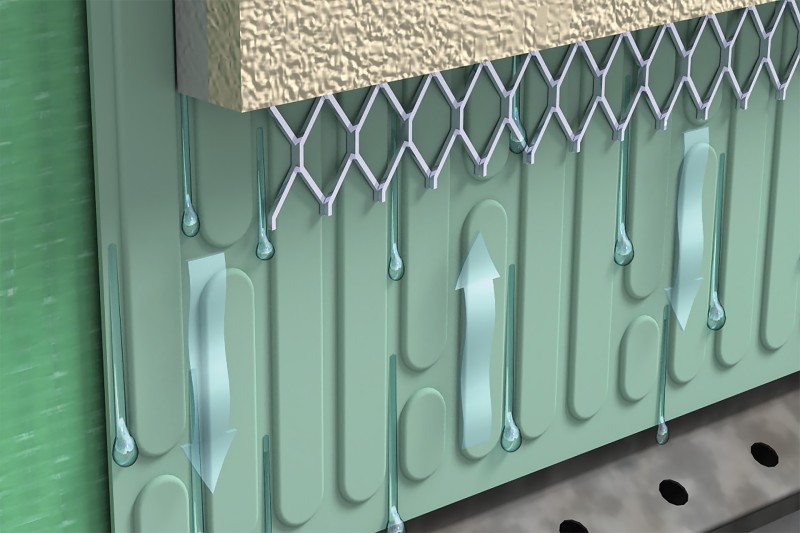

The main difference and features of the system are in the materials and installation methods of the system components prior to thin brick panel installation. Two-inch notched XPS foam is installed over the water barrier-protected wall and held in place by a batten plate assembly. We align the center of the batten plate hole with the center of the wall stud and fasten it with heavy-duty fasteners that can resist overhang (non-structural materials gap) that exists between the point of fastening to the stud and the veneer, typically 2 ½″ +/- depending on job conditions. Thermal non-conductive eyelets create a 100% thermal break between the interior and exterior wall assembly components.

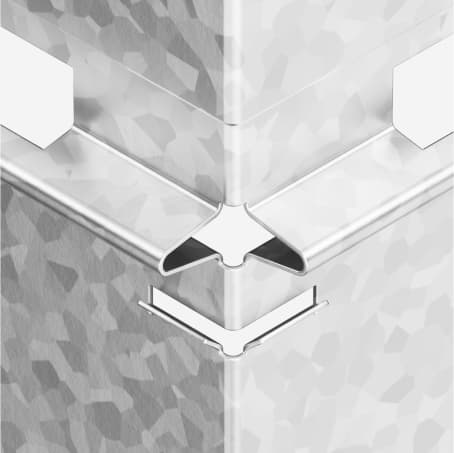

The XPS foam comes pre-notched every 16″ to match wall stud placement. Optional framing stud strapping can provide additional ease in installation, but it increases the cost of the framing part of the project. Therefore, we recommend strapping of the inside and outside corners at a minimum to ensure that there is a structural wall framing component to drive the batten plate fastener to, as the foam thickness might interfere with batten plate and wall stud alignment in those areas. Typically, in this type of assembly, we use XPS drainage mat as it adds another R1 of insulation and acts as one more water barrier behind the veneer.

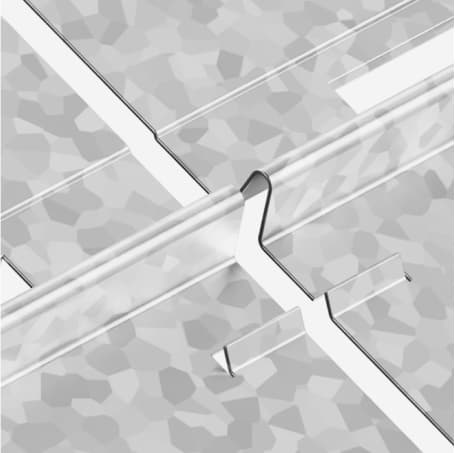

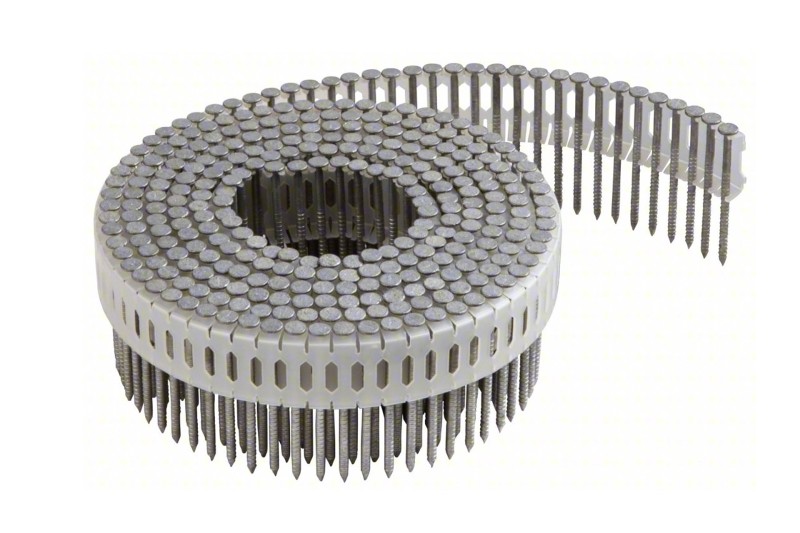

Metal panels are then secured to the batten plates using non-corrosive fasteners. Power tools and fully automatic fastening systems are always recommended to speed up the process of Brick It Panel installations.

Brick It's patented Continuous Insulation method provides a substrate for our Thin Brick assemblies, but it can also be used in combination with Thickset systems to install Thin Stone and traditional cementitious Stucco veneers.

Advantages of CI system

- Adds extra insulation to meet updated building codes for commercial use

- Components are easy to install

- Creates a 100% thermal break between interior and exterior wall assembly components

- XPS foam is pre-notched every 16″ to match wall stud placement

- Metal panels are secured using non-corrosive fasteners

- Can be used with Thin Stone, cementitious Stucco, and Thin Brick assemblies