Cutting Service

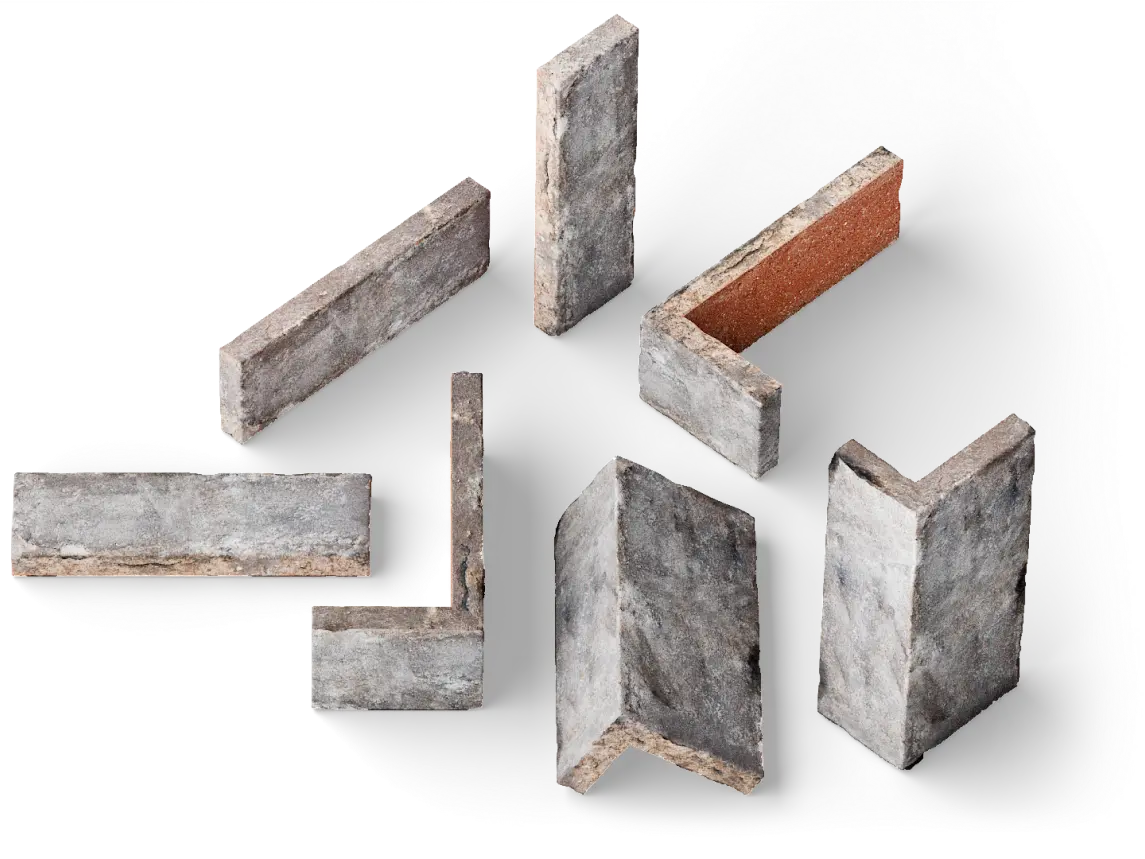

Brick it's cutting service redefines possibilities by transforming standard bricks into thin veneers. Choose from a diverse range of options for your projects while preserving the authenticity of unique or historical bricks not commonly available in thin veneer form.

Methods & Technology

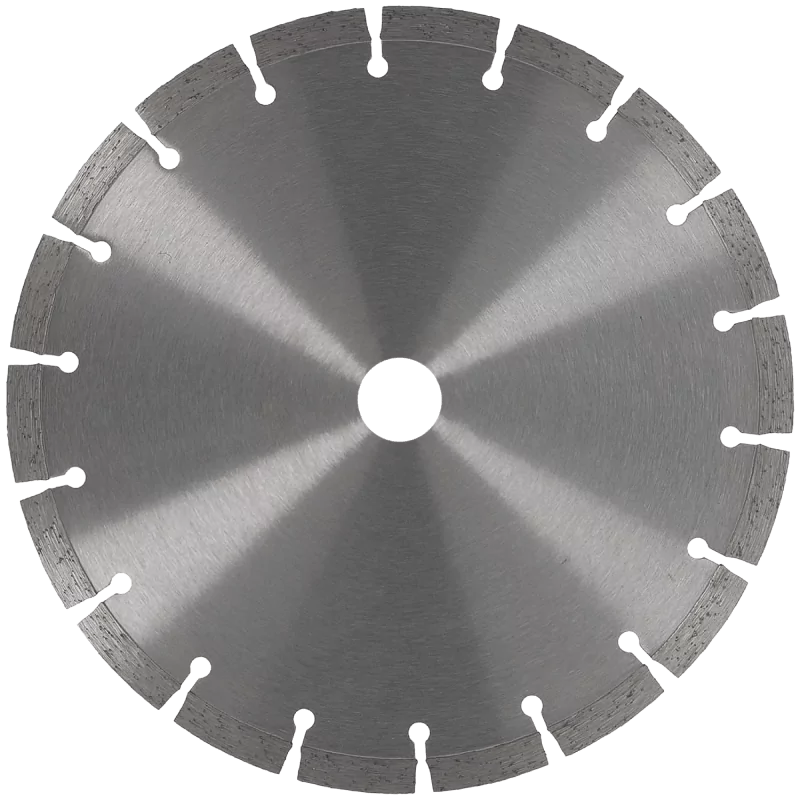

In the era of technological advancement, cutting bricks has evolved significantly. Modern methods have revolutionized the process, making it faster, more efficient, and remarkably precise.

Choose your brick style

and estimate exact cutting cost

Bring Your Own Brick

Take charge of crafting your space to match your vision. Bring your own bricks, exercise control, and witness a project that authentically mirrors your style and preferences – tailored to your specifications through our cutting expertise.

Explore a diverse array of brick options on our website. Choose from our curated selections or bring your own brick for cutting, enabling us to tailor a personalized solution exclusively for you.

Our dedicated logistics team coordinates seamless product pickup from manufacturing plants, or a location specified by you.

We prioritize the most convenient transportation to our facility, aiming for the least inconvenience to our customers.

Our cutting process incorporates essential steps of washing, rinsing, and treatment to safeguard bricks against microbiological contamination.

Our thoughtfully designed packaging minimizes physical strain for workers, enhancing safety and efficiency whether transporting materials on scaffolds or maneuvering goods on man lifts.

Lightweight and appropriately sized, our packages simplify logistics, optimizing time and resources on the job site.

Benefit from dedicated logistics and shipping support, ensuring a smooth and responsive experience for all your logistical inquiries.

Considerations

In project planning, precision is paramount. Material calculations, lead times, and pricing structures form the trinity of considerations. Together, they constitute the essence of successful project management, emphasizing a thoughtful balance between efficiency, timing, and fiscal responsibility.

Material calculations

In the ceramics realm, the pursuit of perfection is intricate, with industry standards shedding light on the unique characteristics of brick products in general. Despite microscopic cracks that elude the naked eye, all bricks inherently carry these natural features. Given the fragile nature of ceramics, breakage during the cutting process is commonplace. We urge customers to consider overages when placing orders, ensuring an adequate quantity despite potential cracks.

For extruded bricks, a 2-3% overage accommodates breakage, while machine-molded bricks benefit from 4-6%, and hand-molded bricks, with more variability, recommend a 7-10% overage. Our commitment to customer satisfaction includes packing the entire order, even cracked pieces, as they often find creative use in projects.

In molded bricks, each full brick yields two thin bricks, making them economical. Extruded full bed bricks, though yielding one thin brick, are a cost-effective option. This nuanced approach to ceramics embraces imperfections, turning them into opportunities for creativity and character in your final project.

Lead time

Lead times can vary due to multiple factors. Our commitment is to strive for a swift turnaround, aiming to cut your order within 12 business days from the order date. Similar to any industry, fluctuations in demand may result in busier or slower seasons. We recommend proactive planning to ensure timely fulfillment of your orders.

How do we charge

Our charging model is based on the quantity of bricks processed through our cutting service, aligning with the delivered full brick amount. The packaged thin bricks may vary slightly due to recovery variations specific to each product. Invoices provide clear and separate listings for full brick purchases from us, ensuring transparency and accurate documentation.

Reclaiming and

repurposing

Revitalizing and repurposing used bricks embodies a sustainable and eco-friendly approach in the construction sector. This method includes rescuing bricks from demolished buildings or construction sites, meticulously cleaning and preparing them for a second life, and subsequently incorporating them into new construction projects.

We are Green!

Our dedication to environmental responsibility goes beyond repurposing used bricks. Acknowledging the significance of sustainable practices in construction, we are committed to minimizing our environmental impact. To achieve this goal, we've instituted various measures in our brick cutting facility to reduce waste and conserve resources.

Water recycling

Additionally, we have implemented a water recycling system in our facility to reduce water consumption. The system collects and filters water used in the cutting process, enabling us to reuse it.

Cut-off waste recycling

One of these measures is the recycling of cut-off waste. We collect and reuse the waste material generated during the cutting process, reducing the amount of waste that goes to landfills.