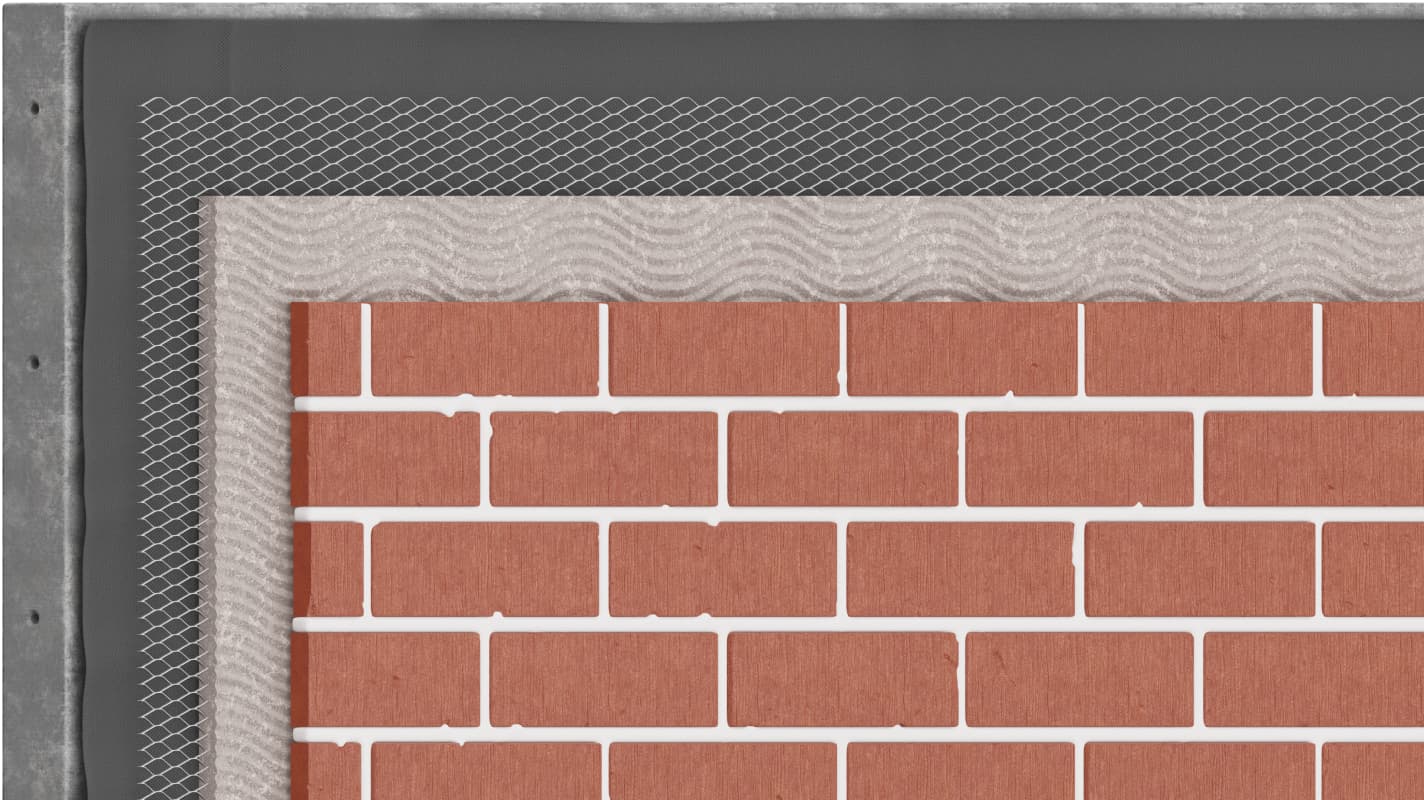

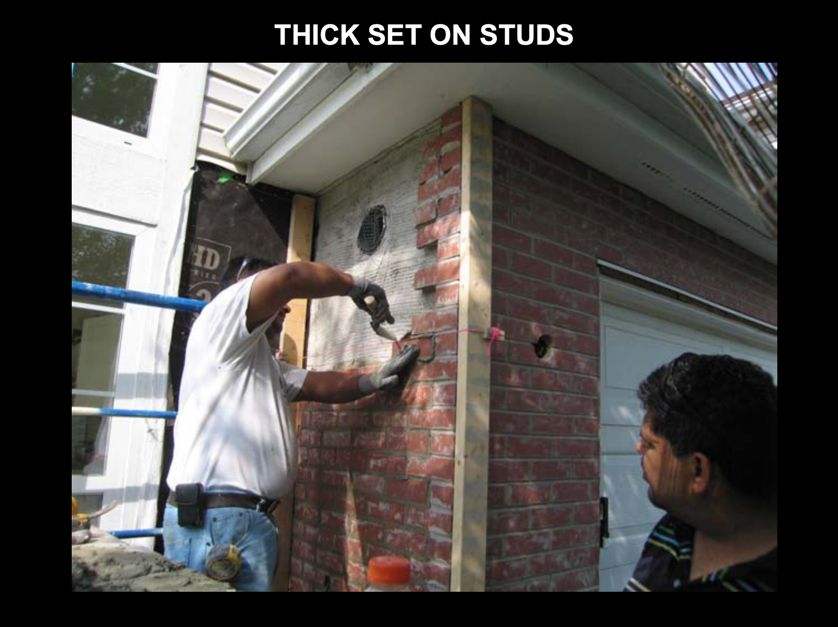

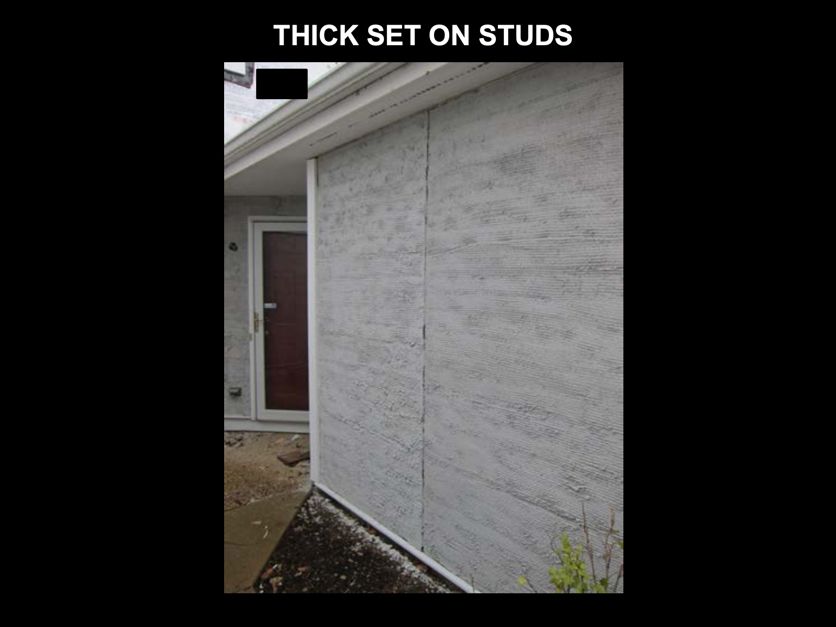

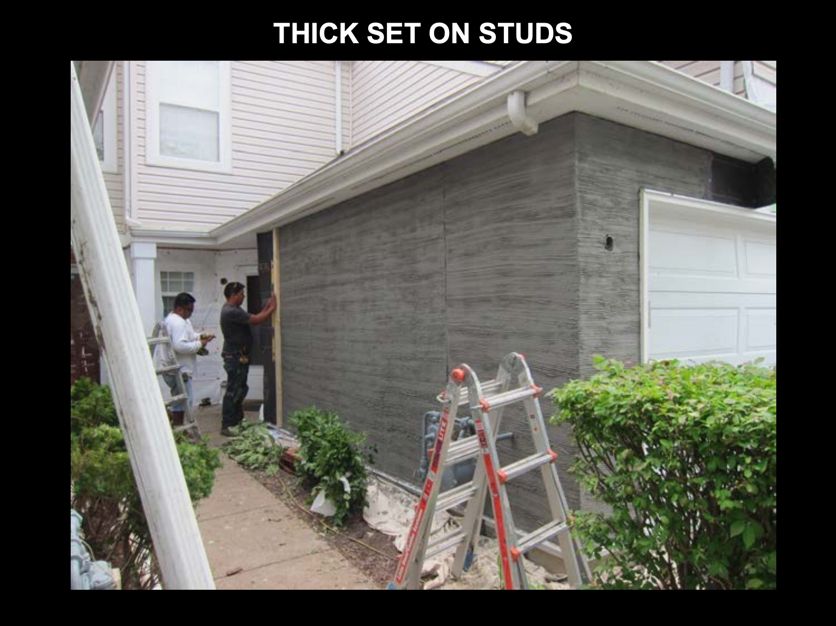

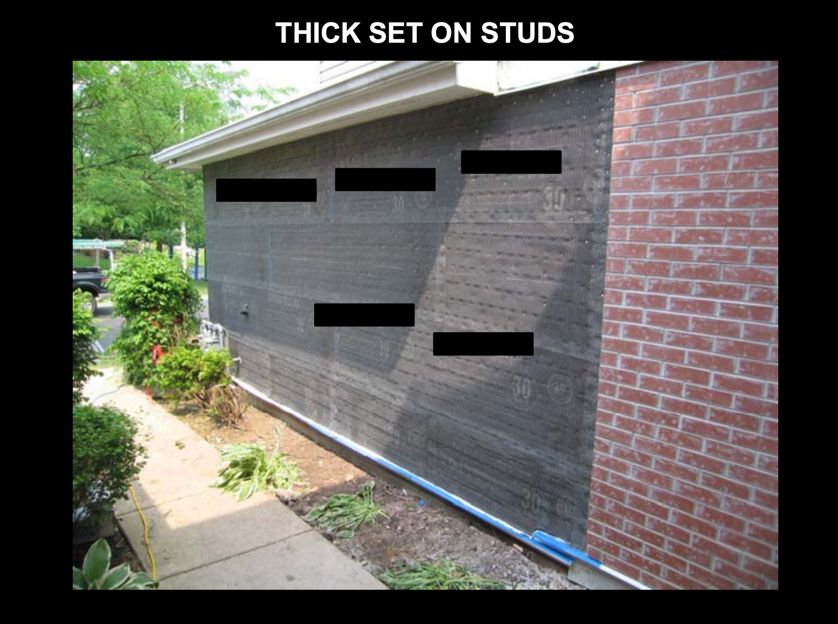

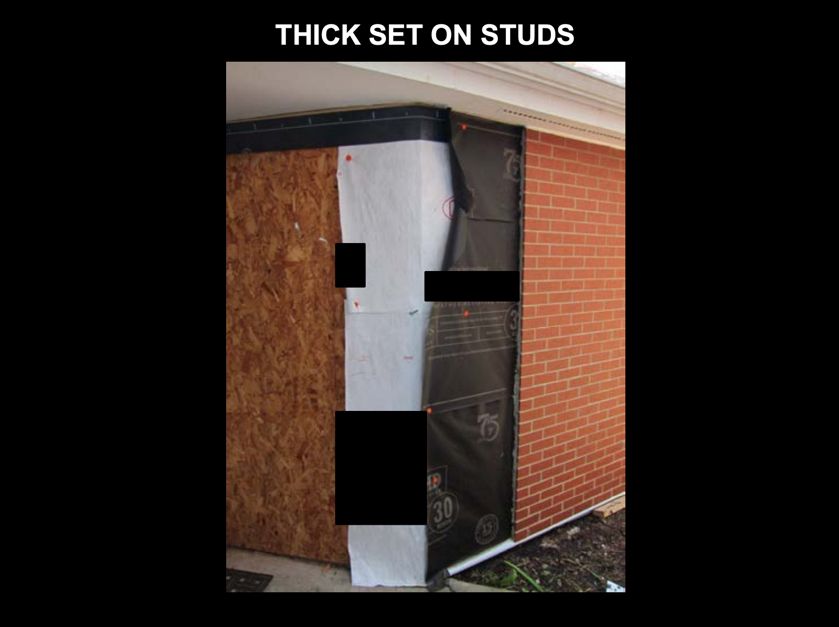

Before placing the brick, the installer must prepare the wall by installing a scratch coat over a self-furring galvanized metal lath, followed by another leveling coat. While placing the brick, the installer must keep them aligned and spaced properly. This procedure is used on interior and exterior walls, including those made of masonry, concrete, steel, or wood stud framing. For a properly assembled system component material list for thin brick installation, heavy-duty self-furring wire mesh and modified mortars specially formulated for real clay veneer adhesion should be used.

Summary

- Prepare the wall by installing a scratch coat over a self-furring galvanized metal lath, followed by another leveling coat

- Keep the brick aligned and spaced properly while placing them

- Use heavy-duty self-furring wire mesh and modified mortars specially formulated for real clay veneer adhesion for a properly assembled system component material list for thin brick installation

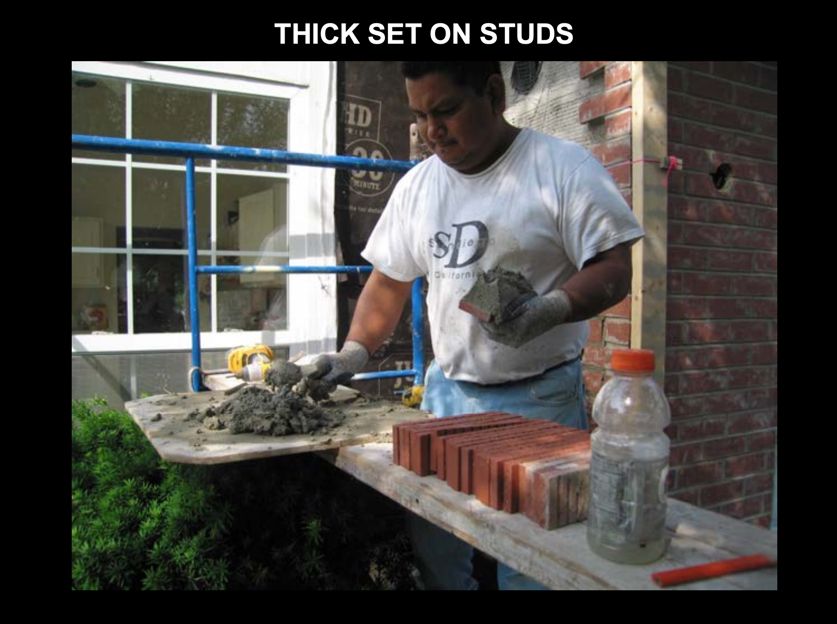

Although the Thick Set system is not complicated to install, it requires more masonry skills, lengthens installation time, and demands more knowledge compared to using one of the metal panel Brick it™ systems. These systems are easier and quicker to install, require less clean up, and create perfectly aligned bricks with less effort and skill. For more information on Brick it™ systems, visit the Why Brick it page.

Note

This information is an overview. For complete installation instructions on all systems, please visit the links provided or speak to a Brick it™ representative.

Ceramic tile installation techniques are often used to install the brick units:

The Tile Council of North America: www.tcnatile.com

The Brick Industry Association: www.gobrick.com